Company Profile

Composite Lining Systems installs GlassBore® Glass-Reinforced Epoxy (GRE) liners into new or used tubing and casing to prevent ID damage caused by exposure to corrosive elements. GRE is extremely durable and has a long history of documented performance. To guard against external corrosion, CLS developed GlassWrap®, an epoxy-based external wrapping system for protected tubing and casing in corrosive downhole environments.

Composite Lining Systems installs GlassBore® Glass-Reinforced Epoxy (GRE) liners into new or used tubing and casing to prevent ID damage caused by exposure to corrosive elements. GRE is extremely durable and has a long history of documented performance. To guard against external corrosion, CLS developed GlassWrap®, an epoxy-based external wrapping system for protected tubing and casing in corrosive downhole environments.

We are proud of our history in US shale operations. CLS has millions of feet of large diameter GlassBore® Premium and API tubing installed into massive water disposal facilities placed strategically within these projects.

We are proud of our history in US shale operations. CLS has millions of feet of large diameter GlassBore® Premium and API tubing installed into massive water disposal facilities placed strategically within these projects.

Our customers in secondary and tertiary production (CO2 and corrosive water injection) form the second largest US market for GRE-lined tubular products.

CLS has applied over 3 million feet of GlassWrap® since 2017. The US shale market is by far the largest beneficiary of this technology; CLS applies GlassWrap® to a significant amount of injection and production tubular products as well. In total, CLS products protect over fifty-three million feet of tubing and casing worldwide.

When cost-effectiveness and workover prevention are central planning strategies, please contact CLS for recommendations. We have years of experience protecting tubing installed into CO2 and water injection wells, corrosive production wells and acid gas injection wells.

When cost-effectiveness and workover prevention are central planning strategies, please contact CLS for recommendations. We have years of experience protecting tubing installed into CO2 and water injection wells, corrosive production wells and acid gas injection wells.

Our products are designed to provide long-term insurance against damage caused by the corrosive elements in your well, matching or exceeding plans of depletion in secondary and tertiary operations and bearing up under rigorous standards for SWD systems.

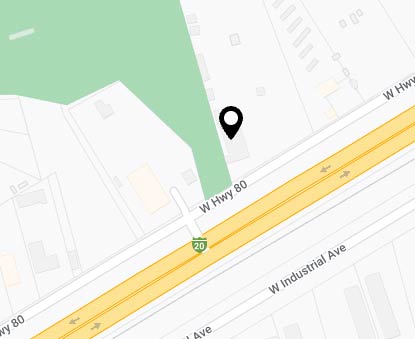

Physical Address

7812 West Hwy 80

Midland, TX 79710 USA

Mailing Address

P.O. Box 50423

Midland, TX 79710 USA

Call/Fax

Ph: 432-617-0242

Fax: 432-617-0244

Email Us